Leku-ona

Leku-ona

The incorporation of Nexo Fittings puts the icing on the cake of the year 2017 at LekuOna Global Solutions During 2017, LekuOna has incorporated several novelties in the services and products that it offers to its customers, in a clear commitment to ongoing improvement.

In little over a week we will welcome a new year and, as is becoming the tradition, we will take the opportunity to look back on the milestones achieved at Leku-Ona Solutions throughout 2017.

On the one hand, one of the biggest novelties of the year has been the incorporation of the company Nexo Fittings to Leku-Ona Global Solutions with the aim of designing, manufacturing and commercialising at a global level its own range of hydraulic fittings for flexible pipes and tubes under the NX brand.

The Nexo Fittings range of hydraulic fittings and connections are manufactured in carbon steel according to the ISO 8434-1/DIN 2353 standard, and are designed for the safe and leak-free connection of metric pipes with diameters from 4 to 42 mm in the light, very light and heavy series.

On the other hand, our ambition to continuously improve our processes and products has been an ongoing feature in 2017. This year we started with the integrated manufacture and assembly of customised non-standard hydraulic reservoirs, with a tailored design and manufacturing, made to the client’s functional, capability and design specifications.

Likewise, we are committed to the incorporation to our catalogue of a new range of hydraulic quick couplings under the name of Ultra High Pressure UHP 100 and UHP 150, which is a result of the strategic decision by Faster to invest in R&D in order to offer top quality products aimed at the industrial sector and high pressure tools.

The investment in machinery was topped off with the purchase of a new BLM tube bending machine which will complete the bending section. This means that the tubes section of Leku-Ona Global Solutions now comprises 6 bending machines with diameters ranging from OD: 4mm to OD: 102mm for bending carbon steel, stainless steel, copper and brass tubes.

Leku-Ona with sports

Like every year, Leku-Ona has strengthened its commitment to the values and philosophy of sport by sponsoring two summer sporting events with a strong following in the area: the Getaria-Zarautz swimming competition and one of the Kintopekos contests.

All of the milestones achieved throughout this year are the result of the effort and work of the team at LekuOna Global Solutions, and which this year also took part in the 10th Company Race organised by Adegi in San Sebastian. Next year there’ll be more to come!

Nexo Fittings, the next leading brand in manufacture and marketing of hydraulic fitting and connections COMERCIAL LEKU-ONA IS THE OFFICIAL DISTRIBUTOR OF THE NEW “NX” BRAND FOR SPAIN AND PORTUGAL

The company Nexo Fittings SL was founded in 2016 in Itziar-Deba, Gipuzkoa (Basque Country, Spain) by the Leku-Ona Global Solutions group, with the aim of designing, manufacturing and globally marketing its own range of hydraulic fittings for pipes and flexible tubes, under the brand name NX (NeXo Fittings).

The Nexo Fittings range of fittings and hydraulic connections are manufactured in carbon steel according to ISO 8434-1/DIN 2353, and are designed for the safe and leak-free connection of metric pipes with diameters from 4 to 42 mm in the series light, very light and heavy.

Internationalisation plan and strategy 2017-2020

The current international economic environment is characterised by its dynamism and requires companies to have a cosmopolitan view of economic activity and business strategies.

To achieve this, Nexo Fittings has developed an internationalisation plan for the period 2017-2020 focused primarily on addressing its expansion into foreign markets in a well-defined and organised manner, with the firm objective of positioning itself as a leader in the global market for pipe coupling and connection solutions for hydraulic systems.

The Leku-Ona family continues to grow

Leku-Ona is able to offer solutions that respond to the needs of the market thanks to the strength of a group formed by Comercial Leku-Ona (manufacture and marketing of a wide range of products and components related to automation in the areas of Hydraulics and Pneumatics , as well as Tube Forming), Urtzinox (design and optimisation of processes related to supply, logistics and manufacturing), MKL (machining and laser cutting), BOSTAK (assembly and hydraulic and pneumatic system solutions), and now NEXO FITTINGS (design, manufacture and global marketing of hydraulic fittings for pipes and flexible tubes).

These all have a strategic approach that is based on an attitude of constant searching and improvement in their corresponding fields of activity, and the synergies that are created between them. The synergies offer many benefits and oblige us to maintain a state of continuous improvement, a feature of the group which makes Leku-Ona Global Solutions especially proud.

More info:

LEKU-ONA_Global Solutions

Pol. Industrial Itziar Nave N2B

20829 ITZIAR-DEBA (GIPUZKOA)

T 943 74 34 50

F 943 74 34 62

E leku-ona@leku-ona.com

www.leku-ona.com

Leku-Ona adds a new tube bending machine to its tubes section THE COMPANY HAS ONCE AGAIN PLACED ITS TRUST IN THE BLM GROUP BRAND WITH THE ACQUISITION OF THE BLM ELECT (ET 102), CAPABLE OF BENDING TUBES OF UP TO 102MM IN DIAMETER

Leku-Ona has recently purchased a new BLM tube bending machine that will complete the requirements of the bending section.

This means that the tubes section of Leku-Ona Global Solutions now comprises 6 bending machines with diameters ranging from OD: 4mm to OD: 102mm for bending carbon steel, stainless steel, copper and brass tubes.

The main features of the new BLM ELECT (ET 102) tube bending machine are:

– The three-dimensional VGP3D graphic programming software: verifies the real possibility of producing the parts, eliminating the risk of collision typical of the first test. It calculates the actual cycle time in advance, reducing the time needed to prepare quotes, and automatically generates the machine cycles.

– Multi-radius: the machine works in multi-radius mode or with different blocks for curves and reverse curves.

– Right or left: you can choose the direction of bending you use most.

– Fixed or variable radius bending in a single cycle: it can mount up to 8 tools at a time, deciding in which position (1, 2, 3, 4 … 8) to put the variable radius.

– It guarantees the maximum repeatability of the part and an unrivalled degree of geometric precisioneven in complex parts.

– It guarantees maximum control of the process: it controls and adjusts to the reactions of the materialand to its elastic return. The ELECT provides several thrust powers (from 2,000 N to 60,000 N), which can be adjusted during the entire bending phase.

Following the new acquisition and thanks to the investment the company has made, Leku-Ona now has the following bending machines:

- – 1 BLM ELECT (ET 102) Maximum bending capacity from OD: 6mm up to 102mm Fully electric machine with right/left bending and 3D visual graphic programming (VGP3D)

- – 1 BLM E-TURN (ET 52) Maximum bending capacity from OD: 6mm up to 52mm Fully electric machine with right/left bending and 3D visual graphic programming (VGP3D)

- – 2 BLM-SMART Maximum bending capacity OD: 22mm in steel tubes and up to OD: 28 mm in copper, brass or aluminium tubes

- – 1 BLM HYDRAULIC NCS832 Maximum bending capacity up to OD: 30mm

- – 1 AMOB MDH 60 Maximum bending capacity OD: 60mm

- – TUBE END FORMING MACHINES

With these machines the range of solutions offered to our customers continues to increase, in line with the search for excellence that characterises Leku-Ona, at the forefront in the sector.

More info:

LEKU-ONA_Global Solutions

Pol. Industrial Itziar Nave N2B

20829 ITZIAR-DEBA (GIPUZKOA)

T 943 74 34 50

F 943 74 34 62

E leku-ona@leku-ona.com

www.leku-ona.com

Leku-Ona will remain open throughout August and is extending its opening hours during the rest of the year The company will remain open throughout August (except Monday 15th) with an uninterrupted service from Monday to Friday.

In line with the company’s policy of providing the best possible customer service, Leku-Ona’s facilities will remain open throughout August with an uninterrupted service from 08:00 to 17:30, Monday to Friday.

Our automated warehouse system means that clients at our direct sales counter will receive their materials immediately, even in summer.

Leku-Ona has also decided to increase its public opening times during the rest of the year:

– Monday to Thursday: 06:00-22:00h

– Friday: 06:00-21:00h

This is all part of our aim to continue providing personalised, quality customer service throughout the year.

Leku-Ona supports two sporting events in July Leku-Ona Global Solutions once again supports initiatives including the Idi Proba and the Getaria-Zarautz Swim Crossing.

Leku-Ona Global Solutions again lent its support to the Errezilgo Kintopeko Idi Probak oxen tests, held from June 23rd to 27th in Errezil.

Some 14 pairs of oxen competed, with Oliden emerging victorious. Amongst other prizes, they received the traditional champion’s blanket sponsored by Leku-Ona.

Moving now from the mountain to the sea, Leku-Ona will also sponsor the 47th Getaria-Zarautz Swim Crossing on July 23rd. More than 2500 swimmers will gather in the Cantabrian Sea to complete the 2850 metres separating the two Gipuzkoan towns.

Leku-Ona Global Solutions supports Basque sport and events which are closely linked to tradition, held in locations close to its Itziar HQ in Gipuzkoa.

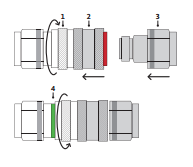

Leku-Ona now offers the new range of Faster® Ultra High Pressure (UHP) quick hydraulic couplings The latest models UHP 100 and UHP 150 have applications in the world of industry and high pressure tools

For more than 30 years, Leku-Ona has been the exclusive distributor in Spain and Portugal of products by FASTER®, a company recognised worldwide for its state-of-the-art and reliable couplings and quick connectors.

One of their latest innovations, launched at the most recent Hannover Messe trade fair, is a new range of hydraulic quick couplings under the name of Ultra High Pressure UHP 100 and UHP 150, which is a result of the strategic decision by the Italian brand to invest in R&D in order to offer top quality products aimed at the industrial sector and high pressure tools.

One of their latest innovations, launched at the most recent Hannover Messe trade fair, is a new range of hydraulic quick couplings under the name of Ultra High Pressure UHP 100 and UHP 150, which is a result of the strategic decision by the Italian brand to invest in R&D in order to offer top quality products aimed at the industrial sector and high pressure tools.

This has led to the new UHP couplings having numerous technological features that make them extremely reliable and easy to use, ensuring exceptional safety for the operators in all aspects of their work.

Faster has replaced radial balls with a Faster patented new technology. Our sector latching system prevents damages on the male groove caused by radial balls in situations of pressure peaks. We have introduced as standard a screw-on safety sleeve with a double visual check with two colours (red and green). This system indicates the complete and correct connection of the two halves.

Moreover, given the extreme working condition of their application (industrial cylinders, rescue tools, lifting equipments..), we have them tested and certified 100%.

Moreover, given the extreme working condition of their application (industrial cylinders, rescue tools, lifting equipments..), we have them tested and certified 100%.

The special laser marking on each single couplings guarantees an excellent legibility of the batch number.

On Faster website it is possible to dowload a certificate that testify that each batch has been tested and approved according to Faster quality standards.

First delivery is expected in May. Meanwhile, the new part numbers for UHP 100 and UHP 150 can already be ordered at Leku-Ona.

In the download section of FASTER portal, you can download the instruction and safety guidelines, with helpful information for a safe and correct use.

In the download section of FASTER portal, you can download the instruction and safety guidelines, with helpful information for a safe and correct use.

For more information on the FASTER® quick hydraulic couplings or their possible applications please contact Leku-Ona on: | T +34 943 74 34 50 | E leku-ona@leku-ona.com

Leku-Ona ran in the 10th Adegi Corporate Race The team from Leku-Ona Group competed in the men’s category and completed the 8.5 kilometres in 42:06 minutes.

On May 7th a team of employees from Leku-Ona Global Solutions took part in the 10th Corporate Race organised by Adegi in San Sebastián.

Participants in the 8.5 kilometre race along the entire coastline of the city enjoyed running next to the sea and the great atmosphere during the event.

Some 530 teams competed this year — a new record, with 60 more teams than at the last event. The race has been getting stronger year after year, and around 2,200 people took part this time.

Employees from Caf, JMA Alejandro Altuna and Schaeffler won the men’s category, whilst the mixed category was won by Salto Systems, Fagor Arrasate and IMQ campeones. The female race was won by the Clinica La Asunción, Eroski and Kutxabank.

Congratulations to all those who took part!

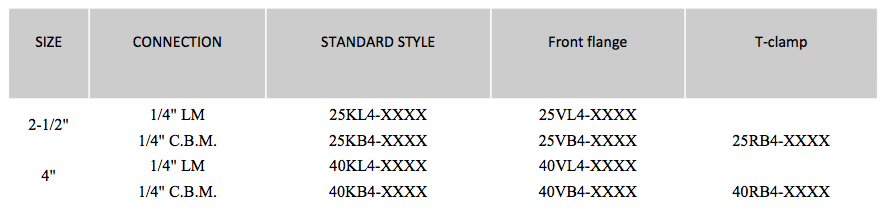

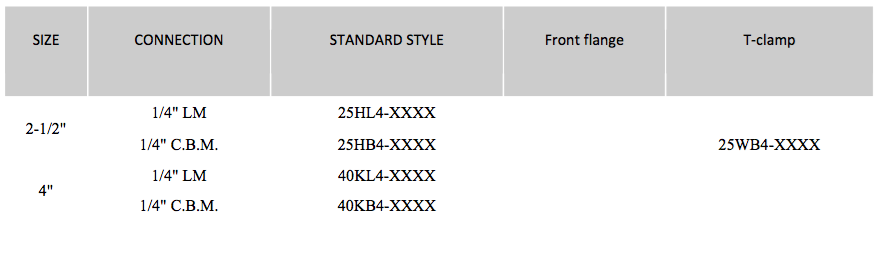

Basic considerations when choosing a hydraulic or pneumatic pressure gauge Selecting the ideal pressure gauge for each installation will depend on the type of assembly, material and ranges.

Measuring the operating parameters of a circuit is essential to be able to verify whether it lies in the correct range or to detect and identify the reasons why it may not be working properly.

A pressure gauge is the instrument used for measuring fluid pressures in both hydraulic and pneumatic circuits, and generally determines the difference in pressure between the fluid and the local pressure.

Given that most pressure gauges measure the difference between the pressure of the liquid and the local atmospheric pressure, the latter must be added to the value indicated by the pressure gauge to find the absolute pressure. A negative reading on the gauge is caused by a partial vacuum.

Pressure gauges are used to measure gauge pressures that vary between 0–1 kg/cm2 and between 0–10,000 Kg/cm2, and to measure vacuum. The gauge accuracy may be between 0.1 and 2% of full scale, depending on the material, design and precision of the parts.

Pressure gauges are usually installed on pumps, portable compressors, industrial equipment, hydraulic and pneumatic systems, instrumentation and pressurised containers, and various aspects must therefore be considered when selecting a gauge:

TYPE:

The different types of pressure gauges available come in a series of copper alloys, stainless steels and nichrome. Copper alloys give better results in some respects, but stainless steels offer greater resistance to corrosion.

Nickel iron alloys are also used. Their coefficient of expansion is very small, meaning that the pressure reading is not affected by the temperature of the instrument.

Mechanical and pneumatic instruments have an accuracy of 0.5% of the scale.

SIZE:

Hydraulic pressure gauges have diameters of 63 and 100 mm, while pneumatic gauges come in diameters of 40, 50 and 63 mm.

ASSEMBLY:

Pressure gauges can be vertical or back mounted, and can also be designed for mounting on a panel using a frontal ring or flange. Each of these details affects the selection of the ideal gauge.

CASING MATERIAL:

At Leku-Ona Global Solutions we can manufacture the pressure gauge casing in plastic, black painted steel or stainless steel. Hydraulic pressure gauges are usually filled with glycerine while pneumatic gauges are usually dry.

The face is manufactured from glass or polycarbonate and the tubular spring (inside) is brass.

Ranges or scales in hydraulic pressure gauges

Hydraulic pressure gauges have scales from 0–0.6 bar to 0–1000 bar (depending on the model), while the ranges for pneumatic gauges are 0-1 bar and 0-20 bar.

For vacuum gauges, the scales for vacuum, vacuum/pressure or pressure are usually -1-0 bar or -1-3 bar. Precision class (3-2-3%) 1 or 1.6. Manufactured in accordance with ASME / ANSI 40-1, B.1985.

Ranges to 30”Hg/6000 psi.

FITTING:

The standard threaded tube is made from brass but Leku-Ona Global Solutions also offers plastic and rustproof (on request). Standard connectors come with male fittings GAS 1/8″, 1/4″,1/2 “, depending on the model (others on request).

The gauge can be mounted to a minimex hose, tubing joint, instant fitting or valve.

Gauge protection

Pressure gauges are protected using a rubber protector or an inline mounted valve, 90º valve, with switch or panel-mounted switch.

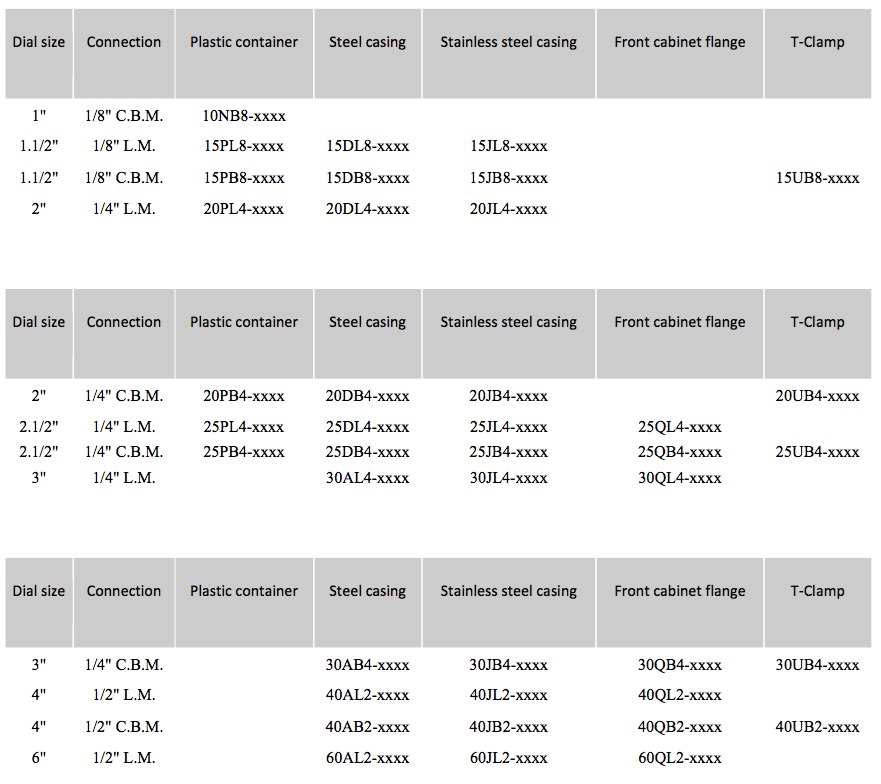

ACCU-AIRE HYDRAULIC AND PNEUMATIC PRESSURE GAUGES

GLYCERINE HYDRAULIC PRESSURE GAUGES

SPECIFICATIONS

STAINLESS STEEL HOUSING/BRASS INTERIOR (DRY)

STAINLESS STEEL PRESSURE GAUGES (DRY)

To complete the model number, add the total value of the pressure scale to identify the initial design. .

PNEUMATIC PRESSURE GAUGES (DRY)

SPECIFICATIONS

For more information on the range of ACCU-AIRE PRESSURE GAUGES available at LEKU-ONA, contact us at: | T +34 943 74 34 50 | E leku-ona@leku-ona.com

SPECIAL CLAMPS

SERIES 0 PIPE CLAMPS

An economic solution for cables, pipes, and hoses

Space-saving and flexible with 6 mm to 22 mm Ø

– Quick assembly

– Little space required

– Guard plate provides stable clamping

– Secure tightening on pipes thanks to pre-tension

– Possibility of combining different diameter pipes

– Fastening with 6 mm Ø welded screws or bolts

– Especially ideal for cables, hoses, gas and oil pipes, and lubricating lines

– Metal pieces also deliverable in stainless steel

CLAMPS FOR CYLINDERS

It is possible to complete different assembly situations with individual pieces or combinations of pieces with practical positioning.

In this context, the following are taken into consideration:

– Pipe or hose assembly on hydraulic cylinders

– Different pipe and hose diameters

– Different distances between pipe and cylinder

– Assembly of various pipe supports for different pipe diameters

HSRS CLAMPS FOR MOBILE HYDRAULIC UNITS

Fields of application

Steel pipe clamps for hydraulic HSRS systems are mostly used in the field of construction machines and public works.

The clamp’s fastening piece is welded edgewise, or flat against the body of the machine or to another construction component. The pipe clamp is screwed.

The clamp’s sturdy construction style provides dampening effects against jolts and vibrations. Thanks to the clamp’s low height, it is always possible to place hydraulic pipes later, for example after additional equipment has been mounted on construction machines.

Elastomer cover

Steel pipe clamps for hydraulic HSRS systems are supplied with an optional elastomer cover.

Advantages:

- it is possible to fasten different pipe diameters with a single clamp

- improved vibration and noise dampening

- secure fastening of pipelines and delicate flexible pipe conduits as well

Materials:

Santoprene 64° Shore A

– high resistance to oil and outdoor weather

– resistance to temperatures between -40 and +125°C

STRUTS – ROUND STEEL CLAMPS WITH BASE FOR PIPE.

Above all, these clamps are ideal for fastening pipes that experience thermal expansion. As an option, pipes can be firmly fastened through the clamp, or have a sliding adjustment.

Execution

Round steel clamps are manufactured in these two versions:

- RUBS-round steel clamps according to DIN 3570 with two bolts, and

- RUBLS-round steel clamps with four bolts, using the bases for KUPK or KUPL

Round steel clamps are supplied for pipe diameters between 17 and 762 mm. The bases for pipes are manufactured in a short and long version, and are made of polypropylene, polyamide, steel, and high-grade steel.

For more information on the range of Clamp products available at LEKU-ONA, contact us at: | T +34 943 74 34 50 | E leku-ona@leku-ona.com

sending...

sending...