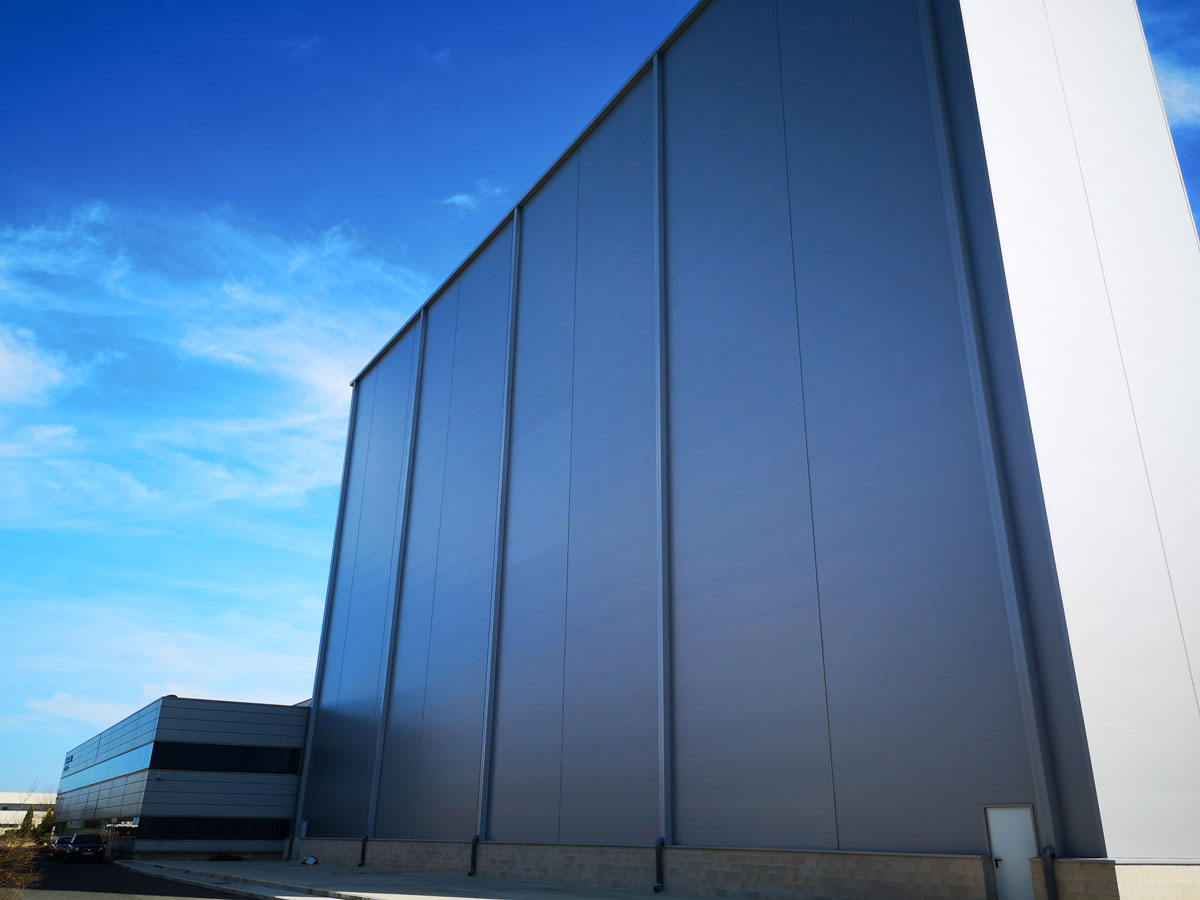

Automatic storage systems for pallets are solutions that use automated mechanisms for the handling of loads. It offers a high storage density thanks to the reduction of the work corridors and its height growth capacity. It also uses minimum response times. Its reliability allows the immediate inventory of stored products and minimizes errors in the handling of loads.

With the new automated pallet storage system we get:

- Increase our storage capacity thanks to the high degree of compaction, the use of height

- Automated and digitized material entry system

- Automated system extraction of product through stacker cranes in order to optimize all physical movement processes within the warehouse, which in turn is connected to the “host” of the company from where the orders are received to process the different transactions from the warehouse.

- Considerable time saving in material delivery

- Reliability and versatility. As long as the merchandise conforms to very stringent standard characteristics of palletizing, within the robotic warehouse we can store any type of merchandise.

Leku-Ona Global Solutions, in its effort to show its processes, services, installations and professionals with total transparency, has launched a Youtube channel, where you can find audiovisual items about the group’s different companies, such as

Leku-Ona Global Solutions, in its effort to show its processes, services, installations and professionals with total transparency, has launched a Youtube channel, where you can find audiovisual items about the group’s different companies, such as

sending...

sending...